Blog

The Big Finale - Ellen's Design Challenge - No.6

By Karl Champley

After an interesting finale, WE WON IT & proud to be carpenter of the week for the third time.

Let me share a few behind the scenes moments.

A unique piece with the ability to double in size which can be used & appreciated at any angle! We built the shelves to display items in addition to supporting the stools with out disruption to the contents. A great piece of furniture for a variety of spaces, large or small.

It was originally a taller unit with two additional purple heart shelves attached to three columns with a round disc like acylic LED light fixture we made by hand. The height of our final piece was within the parameters of competition rules and requirements. However, just hours prior to the finale presentation, we were told the bad news. Our piece was too tall for the stage due to the additional platform added to the presentation circle for the finale. We had no choice but to give the crew the green light to remove the top section leaving only the base! Whilst only half of the design remained, the piece still presented beautifully as well as remaining multi functional and within the guidelines of the final challenge.

This last challenge was difficult for the designers as the boundaries where wide open. It was a privilege to be working with two very beautiful species of wood, Purple Heart and Zebra Wood. A celebration of colors.

The build:

First up I laminated everything ASAP to enable it to dry overnight. The laminated purple heart was for the stools and zebra wood for the shelves. There was not one straight piece which is common, so each one was run through the table saw to square the edges and then glued and clamped.

Once fully dry, each slab was fully planed and sanded.

Purple Heart is an amazing species! Its rough form has a dark brown/purple finish to it. As soon as you cut it, it becomes bright purple. If you leave it untreated it returns back to original color. I used a danish oil after I fully sanded all surfaces with a number of high grit sanding pads to make it smooth as a babies butt. The oil brings out the natural beauty while maintaining the color.

It is very expensive with limited supplies on our planet so I don't want to encourage anyone to use this species in large quantities!

I fabricated the countertop shell out of 5/8" euro ply and laminated all sides with Zebra wood veneer to match the solid Zebra wood shelves. This top was made for an additional acrylic countertop insert. I lined the interior with felt to enable the additional acylic countertop to slide in and out easily. I also laminated the Zebra wood one inch into the interior to give the appearance of a solid slab.

The leg supports where made out of ABS/PVC as our wood lathes where not large enough to turn our wooden legs - our original plan. You will notice that there are three legs not four as a three legged table or chair will never rock. The shelves where all mitered using dominos tenons for strength and to keep all fasteners hidden.

The stools were also mitered and fastened with domino tenons for strength with the addition of two Zebra wood tounges for strength and appearance. These stools were rock solid and built to a height to suit the pull out countertop.

I turned a Zebra wood dowel to create a handle. This was inserted into the acylic sheet to enable ease of operation. The shell was notched at the bottom to account for the handle to ensure the insert remained flush.

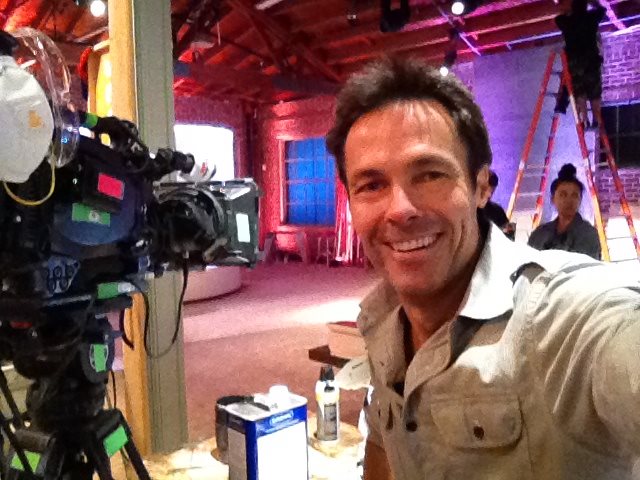

Oh....look! Another camera! :) Let me tell you, it's a very different experience to build furniture with sometimes four or more cameras shooting you.

As soon as we finished our piece we cleaned up and were off in our own limo to be judged.

Miss awesome & I in the back with our producer and the crew in the front :)

We had no idea where we were going.

That was OK as this was my first time to chill since we first started this challenge.

We made it to the finish line even though this was only half of our finished piece of furniture.

Chip and I showing Ellen our finished work. Yep, she is genuinely passionate about furniture and I really appreciated her excitement for the pieces we built.

******

I wanted to take this opportunity to thank all of you who supported Katie and I on Ellen's Design Challenge!

I also want to thank Ellen and A Very Good Production Inc. for enabling me to be part of this production. Thank you to HGTV, A Smith & Co. productions and the entire crew for working side by side with all of us through thick and thin. I will miss the safety meetings as well as all of those fine tools!!!

It was great to have met all of the other fine designers and to have worked side by side with the other talented carpenters. It was truly a great group that is not so common these days!

A special thank you to Katie Stout for challenging me with some special pieces I never thought I would ever build. You are an inspiration and on your way to becoming a stand out designer!

Thank you for our win!

VIDEOS: To check out the Carpenter of the week and Judges' deliberation videos:

http://www.hgtv.com/shows/ellens-design-challenge

Posted on 03/09/2015 at 02:56 PM